Flowable Fill and Self-Consolidating (SCC) Concrete

Flowable Fill Concrete Overview

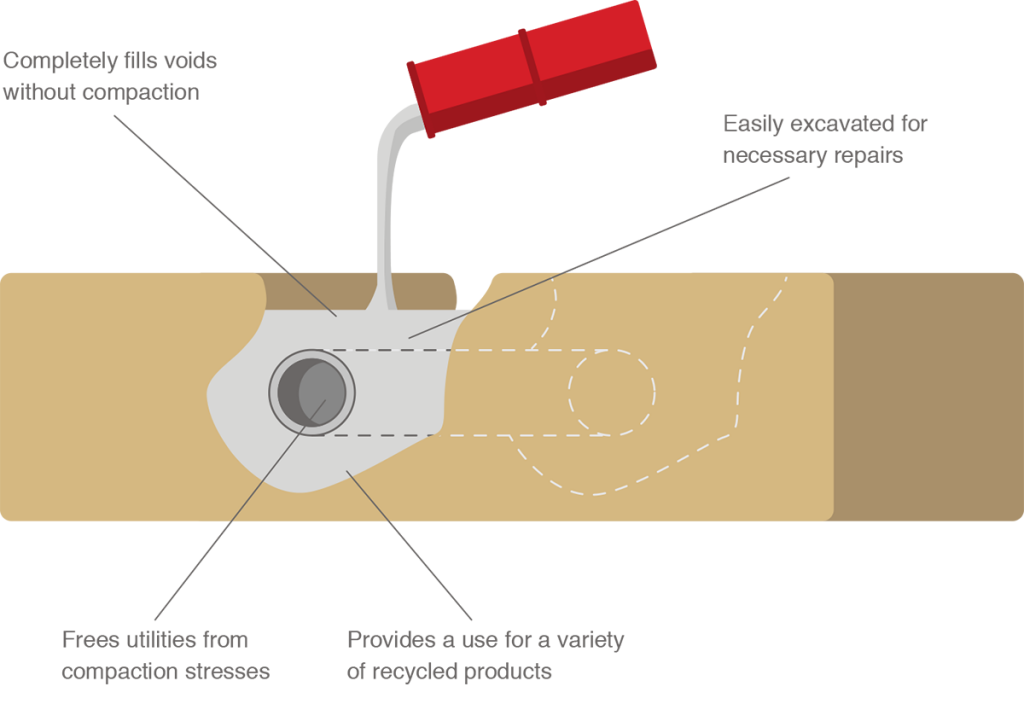

Flowable fill is a self-compacting low-strength material that is placed as a liquid. The slump is usually greater than 8 inches, and the self-leveling material can be placed with minimal effort, as it does not require tamping or vibration.

Why is flowable fill used?

Flowable fill is great for fixing problems that originate from poorly compacted soil or granular fill. For instance, flowable fill is typically used as backfill for sewer trenches and pile excavations or structural fill for foundation subbase and pavement bases.

This economical alternative offers considerable savings in labor costs, time, and equipment. It’s even great for filling inaccessible areas, such as underground tanks, and it provides a safer alternative as workers don’t have to be in holes to complete a job.

How is it delivered?

Flowable fill is delivered by a ready mix concrete truck and is placed via chute in its flowable condition directly into the area that needs to be filled. This unique material can be conveyed by pump, chute or bucket, and thanks to its fluid properties, it can flow long distances.

What else should you know about flowable fill?

Flowable fill is not concrete, which means it doesn’t need to be cured like concrete. However, this product should be protected from freezing until it has fully hardened, so be sure to take this into consideration if using on your project.

Flowable Fill Concrete Applications

Backfill Material

Backfill Material is used for a variety of reasons, whether you need to secure a retaining wall or support underground pipes. Concrete backfill is not only a strong option, but also a durable way to keep your projects steady for many years.

Self-Consolidating Concrete (SCC) Overview

Self-consolidating concrete (SCC) does just as it says; it consolidates itself as it flows into place without separating. Using SCC mixes allows for quicker placement and a more uniform surface finish without requiring manual finishing techniques. Best used in applications such as retaining walls, bridges, and dams that tend to require higher-strength concrete, SCC is a great alternative to flowable fill.

Self-Consolidating Concrete (SCC) Applications